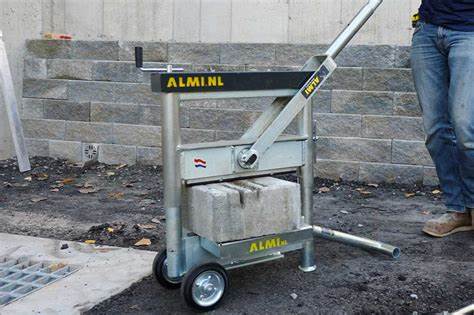

If you regularly cut bricks, paving slabs or concrete blocks, you know how exhausting hand tools and saws can be. A manual block splitter is a simple lever‑driven machine that makes these jobs quicker and cleaner. Instead of wrestling with dust, noise and jagged cuts, you insert the block, pull the handle and the mechanism applies a controlled force through a hardened blade.

In this blog, we’ll explore how manual block splitters work, why they’re a great choice for masonry and hardscape projects, and when you might want to consider a block splitter rental to keep your budget under control.

What is a Manual Block Splitter?

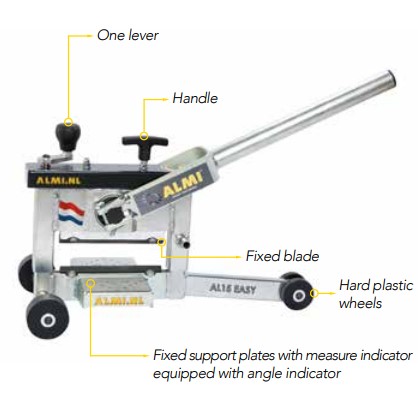

A block splitter, sometimes called a brick or slab splitter, is a manually operated device with a blade and lever mechanism designed to cut and shape bricks, blocks and paving slabs. You place the material on the splitter bed and use the lever to apply force along a predetermined line, which splits the block cleanly.

And because the cut is generated by a lever rather than a motor, block splitters are quieter and produce far less dust than power saws. They’re widely used in construction, landscaping and paving because they combine precision with ease of use.

Advantages of Using Manual Block Splitter?

There are several advantages to choosing a manual splitter over a saw or chisel:

Precision and Efficiency

The mechanism produces clean, straight cuts quickly, improving the finish and saving time. That means less time tidying up edges and more time laying blocks.

Less Dust and Noise

Unlike saws, block splitters don’t generate clouds of dust or deafening noise, making them ideal for residential work or areas with noise restrictions.

Lower Maintenance

Manual splitters have fewer moving parts than power tools. This reduces the risk of mechanical failure and keeps running costs low.

Cost‑Effective

Hiring or buying a manual splitter is often cheaper than purchasing a high‑end saw, especially for occasional projects.

Minimal Skill Required

With basic instruction, anyone can produce professional‑looking cuts. Unlike using a hammer and chisel, the splitter does the hard work and requires little operator skill.

How to Use a Manual Block Splitter

Using a block splitter is straightforward, but proper technique keeps you safe and improves results. Here’s a step‑by‑step summary of the process:

- Wear protective equipment: Always wear safety goggles, gloves and sturdy boots.

- Adjust the cutting height: Different models have adjustable beds. Set the blade height to match the thickness of your block.

- Mark the cutting line: Use chalk or pencil to mark where you want the split.

- Position the block: Place the block under the blade so the cutting line aligns with it.

- Apply pressure: Pull the lever down steadily. The blade descends and splits the block along your mark. Use additional leverage (a pipe over the handle) if necessary.

- Inspect the cut: Remove the pieces and smooth any rough edges with a chisel or sanding block.

For repeated cuts on identical blocks, once the height is set you can work through them quickly without further adjustment.

Manual vs. Hydraulic Block Splitters

Hydraulic splitters use a foot pedal or hydraulic cylinder to raise the platform towards the blade. They make cutting easier because the machine supplies most of the force, but they cost more, weigh more, and have more components that can fail. A manual block splitter, by contrast, is lighter and has fewer parts – making it easier to transport, maintain and repair at the cost of requiring more manual effort to operate.

For most paving, patio or garden wall projects a manual splitter provides more than enough power. Hydraulic models may be preferred for heavy‑duty commercial work, or when splitting very dense materials.

How to Choose the Right Block Splitter (Rent or Buy)

Not every project requires the same equipment. Some trusted guides differentiate between a standard block splitter, which is lightweight and portable for small or DIY jobs, and a hydraulic block splitter, which offers up to 8 tonnes of cutting force for dense bricks and large‑scale projects. When deciding whether to buy or arrange for a block splitter rental, consider the materials you’ll be cutting, how often you’ll use the tool, and your budget.

For occasional jobs, hiring a masonry block splitter from a reputable supplier like Multiquip UK makes sense. You get a calibrated machine delivered when you need it and avoid long‑term storage or maintenance.

Masonry Applications and Hardscaping

Block splitters are versatile tools used across construction and landscaping:

- Construction: It is used in splitting bricks and blocks to size for walls, foundations and other structures.

- Landscaping: Creating pathways, patios and retaining walls where consistent cuts produce a professional finish.

- Paving: Cutting paving slabs to ensure neat edges and tight joints.

- DIY projects: Building garden features or custom outdoor spaces at home.

Because manual splitters are quieter and cleaner than saws, they’re ideal for working in residential gardens or built‑up areas where dust and noise can be a concern.

Tips for Maintenance and Safety

Keeping your manual splitter in good condition extends its life and ensures safer operation. Follow these guidelines:

- Wear PPE every time: Safety goggles, gloves and steel‑toed boots protect your eyes, hands and feet.

- Work on a stable surface: Ensure the splitter sits on a flat, level base free from tripping hazards.

- Inspect the equipment: Check for signs of wear or damage before each use. Replace damaged blades or components immediately.

- Follow manufacturer instructions: Adjust the cutting height and use the lever correctly as described by the manufacturer.

- Store it properly: After use, clean the machine and store it indoors to prevent rust. Replacement blades should be kept dry, and replaced when they become blunt.

Frequently Asked Questions

How much does it cost to hire a block splitter?

Prices vary depending on the model and rental period, but hiring a manual block splitter is usually quite affordable when compared with the cost of buying one. Contact Multiquip UK for a competitive quote and to find the right machine for your project.

Can a block splitter cut natural stone or reinforced concrete?

Standard manual splitters are designed for bricks, blocks and paving slabs and may not be suitable for hard natural stone, or concrete with rebar. For those materials, a masonry saw or specialist cutting tool is recommended.

How do I maintain my manual block splitter?

Clean the machine after each use, inspect and replace blades as needed and store it in a dry place. Periodically lubricate moving parts and check for wear or damage before operation.

Can a manual block splitter cut curves or angles?

Block splitters are primarily designed for straight cuts. Creating curves or angles is difficult and usually requires a masonry saw or angle grinder to achieve the desired shape.

Conclusion

In summary, a manual block splitter is a powerful yet simple tool that makes masonry work easier. By delivering clean, accurate cuts with minimal dust and noise, it helps you finish projects quickly and professionally. Whether you’re building a garden wall, laying a patio or working on a commercial site, the right splitter will save time and effort. If you need a masonry block splitter, talk to our team at Multiquip UK. We offer high‑quality manual block splitters, expert advice and convenient delivery across the UK.