Diamond tools are special cutting and grinding tools that use diamonds, the hardest natural material on Earth, to do tough jobs accurately. These tools are important in many industries, and we’re going to shine the spotlight on them in this blog.

Read on to learn more about what diamond tools are, how they are made, and more with the Multiquip team!

Key Points: What Are Diamond Tools?

- These tools are cutting, grinding, and polishing instruments that use diamond particles to work better

- They are used a lot in construction, manufacturing, and precision industries

- They are very hard, last a long time, and cut very well

- Common types include diamond saw blades, drill bits, grinding wheels, and polishing pads

- These tools are made using man-made or natural diamonds stuck to metal, resin, or ceramic bases

What Exactly Are Diamond Tools?

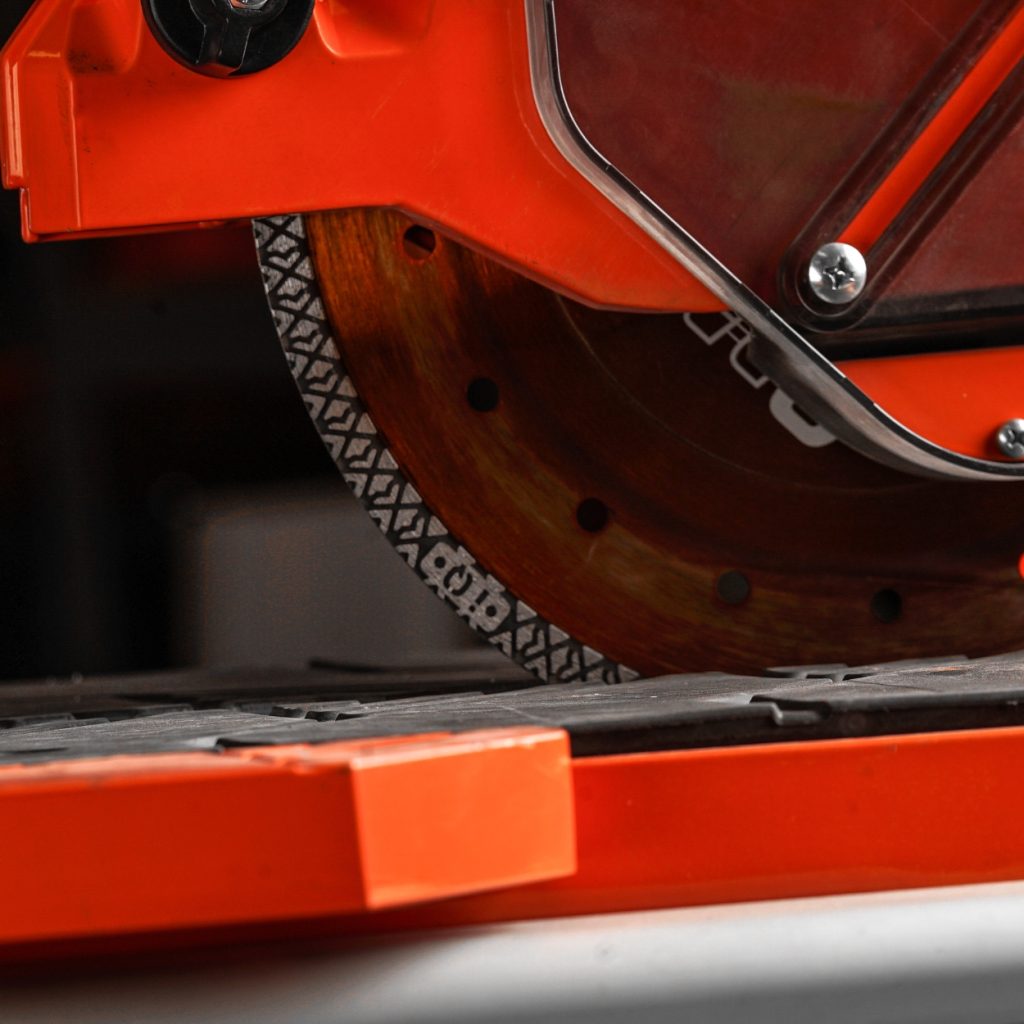

These tools use diamond fragments to cut, grind, or polish hard materials like concrete, stone, ceramics, and metals. Their hardness ensures sharpness and precision, as well as durability.

The General Purpose Supreme Blade exemplifies these qualities. Designed for concrete and masonry cutting, its carefully placed diamond segments enable fast, durable performance, making it a near-essential piece of kit in construction and stonework.

How Are Diamond Tools Made?

They are crafted using advanced technology and the following basic process:

- Choosing the Diamonds: Natural or synthetic diamonds are selected, with synthetics preferred for consistency and cost.

- Preparing the Diamonds: Crushed into controlled sizes for optimal performance.

- Making the Base: A metal base (e.g., cobalt, bronze, or steel) enhances durability and heat resistance.

- Bonding the Diamonds: High pressure and heat fuse diamonds with the metal base.

- Shaping the Tool: The bonded material is precisely formed into blades, drill bits, or grinding wheels.

Why is Diamond Used as a Cutting tool?

The answer lies in its unmatched hardness and wear resistance. Diamonds can cut through the toughest materials, including concrete, stone, and metal, with minimal wear, making them the ideal choice for high-performance cutting tools.

This meticulous manufacturing process creates durable, high-quality tools for tough jobs. For example, the 14′ General Purpose Laser Blade uses laser welding for superior strength, ensuring precise diamond placement and long-lasting, high-performance cutting.

Types of Diamond Tools

There are many different kinds of diamond tools, each made for specific jobs. Here are some common types:

- Diamond Saw Blades: For cutting hard materials in construction and stone processing

- Diamond Grinding Wheels: Used for precision grinding in manufacturing and metalworking

- Diamond Drill Bits: For drilling through hard materials in construction and mining

Each type of diamond equipment has a special job in industries from construction to stonework and even making electronics.

For example, tools like saw blades are really important for cutting hard materials in building projects, while polishing pads are used to make stone surfaces smooth.

Why Use These Special Tools?

Using diamonds in cutting tools has many advantages that make them better than ‘regular’ cutting and grinding tools. The benefits in the section below will help you understand why diamond tools are so important in many industries.

Benefits of Diamond Tools by Industry

Learn how these tools boost efficiency, precision, and durability across industries – from construction to aerospace – with unmatched cutting and grinding performance.

Construction

- Enables faster, cleaner cuts in concrete, asphalt, and masonry

- Reduces downtime with long-lasting blade life

- Supports precision work on-site with minimal chipping

Manufacturing

- Increases productivity in machining hard metals and composites

- Enhances accuracy and consistency in production lines

- Lowers overall tool replacement costs

Stone and Tile Processing

- Allows for smooth, high-quality finishes on natural and engineered stone

- Cuts delicate materials like ceramics with precision and minimal breakage

- Improves efficiency in cutting, grinding, and polishing applications

Automotive and Aerospace Industries

- Provides tight tolerances required in advanced materials machining

- Extends tool life when working on heat-resistant alloys and composites

- Reduces waste and improves safety in precision engineering

Medical Equipment Production

- Delivers exact cuts for critical components with no margin for error

- Ensures superior surface finishes required in surgical instruments

- Enables the shaping of ultra-hard materials used in implants and devices

Material Compatibility & Common Uses of Diamond Tools

Diamond tools are designed to handle some of the toughest materials used in construction and manufacturing. Their extreme hardness and precision make them ideal for cutting, drilling, and grinding a wide variety of substrates.

At Multiquip UK, our diamond tools are frequently used on:

- Concrete and reinforced concrete – for structural and surface cutting in civil and commercial projects.

- Masonry and brickwork – ensuring clean, accurate cuts with minimal chipping.

- Stone and ceramics – delivering precision finishes on natural and engineered materials.

- Asphalt and tile – achieving fast, controlled cuts for repair and installation work.

- Metals and composites – in specialised applications requiring heat-resistant and wear-resistant tooling.

Because of this versatility, diamond-tipped tools are trusted across construction, utilities, and industrial engineering sectors, providing the performance and reliability professionals depend on every day.

Other Applications of Diamond Tools

Diamond tools are used in many different industries and for many different jobs, showing how versatile and important they are in the modern world. Beyond construction, they’re also commonly seen in:

- Mining: Drilling and getting minerals out of hard rock

- Electronics: Making parts for computers and cutting circuit boards precisely

- Stone Processing: Cutting and polishing natural stone for buildings and decorations

Caring for Your Tools

Proper care extends the life and performance of diamond tools. Here’s how you provide that care:

- Clean them regularly: Remove dirt and buildup to prevent clogging.

- Store them properly: Keep tools dry to avoid rust and damage.

- Use them correctly: Follow manufacturer guidelines to prevent wear.

- Keep them cool: Avoid overheating to protect the tool and material.

- Inspect them often: Check for wear and replace when necessary.

Following these steps ensures longevity, especially for high-quality tools like the 20″ General Purpose Supreme Blade. Proper maintenance preserves precision, improves work quality, and reduces costs.

How to Choose the Right Diamond Tool

Selecting the right diamond tool for your application is essential to achieve maximum performance, durability, and safety. A few key factors can guide your choice:

- Material Type: Match the blade or bit bond hardness to the material’s density – harder bonds for softer materials like asphalt, and softer bonds for hard materials like granite or reinforced concrete.

- Application Method: Choose between wet and dry cutting options depending on site conditions and dust-control requirements.

- Tool Design: Select segment height and shape based on depth and precision needs – continuous rims for fine finishes, segmented rims for faster, cooler cutting.

- Equipment Compatibility: Ensure voltage, arbour size, and mounting fit your saw, grinder, or core drill.

- Operational Frequency: For heavy-duty or daily use, invest in premium laser-welded blades or bits designed for extended service life.

If you’re unsure which solution suits your project, our technical team can help you identify the right tool from Multiquip UK’s extensive range of diamond blades, drill bits, and grinding accessories, ensuring optimal results every time.

Explore our full range of diamond tools in the UK to find professional-grade solutions for cutting, drilling, and grinding applications.

What Might the Future Hold?

As technology gets better, the future of diamond tool technology looks promising, with several new ideas that could make it work even better and be used for more things. Future improvements might include:

- Nano-diamond Coatings: Better precision and durability for very small cutting jobs

- Smart Tools: Tools with built-in sensors to check how they’re working and make them work better

- Eco-friendly Production: Making tools in ways that are better for the environment

- Advanced Composites: New materials for the base to make tools work better for special jobs

Conclusion

Now you know what diamond tools are, and why they lead the way in precise cutting and grinding. You also know why they’re vital across industries from construction to high-tech manufacturing, and how these specialised instruments use industrial-grade diamonds to achieve superior hardness, durability, and precision.

Choosing the right tool enhances efficiency and quality (especially for cutting and drilling projects), with continuous advancements offering solutions for even the toughest materials. Investing in high-quality tools from trusted brands like Multiquip UK improves project outcomes. As technology evolves, diamond tools will continue to revolutionise industrial and construction processes.

Frequently Asked Questions

They’re commonly used to cut, grind, or drill tough materials such as concrete, masonry, ceramics, and stone. Professionals rely on them for achieving clean, precise results on-site. Their strength and durability make them essential in demanding construction and manufacturing environments.

Service life varies depending on the material being cut, the bond type, and the way they’re used. High-quality blades made with laser-welded segments generally last much longer than entry-level options. Regular maintenance and correct operation extend their lifespan significantly.

Some blades are designed for dual use, while others are made specifically for either wet or dry cutting. Wet use helps with cooling and dust control, improving safety and blade longevity. Always check the manufacturer’s specifications before starting a job.

Diamond is the hardest naturally occurring substance, capable of cutting through dense, abrasive materials with ease. It offers sharpness, stability, and minimal wear, even under high friction. This makes it a trusted choice for consistent, precision performance.

After each use, clean the blade to remove debris and avoid overheating during operation. Store them in a dry place to prevent corrosion and inspect regularly for signs of wear. Following proper care routines helps maintain efficiency and cutting accuracy over time.

Multiquip UK offers a complete selection of cutting, drilling, and grinding solutions for professional use. Each product is engineered for precision, durability, and reliability in challenging environments.